And really, will anyone miss it?

Not me. Not at all. Oh sure, like the buggy whip, 8-track, and the fax machine, resin aftermarket was the bees knees in its day. It was and is far cheaper than using injection molded plastic. Making masters and casting resin parts from them was a viable way to spread some extra model detail to the masses.

But the downsides… the warping, the pitting, the misshapes and the shrinkage. Oh and hacking away at the pour plugs with the razor saws. And then there is the fitting… don’t get me started on the fitting. Then there is the whole cancerous dust thing to worry about. Nope, I won’t be missing any of that.

Ok, Ok, there IS some upscale resin out there. The modern stuff made by those who know what they are doing is actually miles better than most of the ‘garage industry’ resin bits. Sure, I will give you that. I have some of it and the quality is actually rather impressive.

But I still gotta hack it out, and fit it in.

Up until recently, resin was still king because due to the resolutions of the 3D printers. Resin got you smooth parts without those 3D print lines. Now the cost of the printers is tumbling while the resolutions are skyrocketing and we are getting 3D prints that are just as good, if not better than resin.

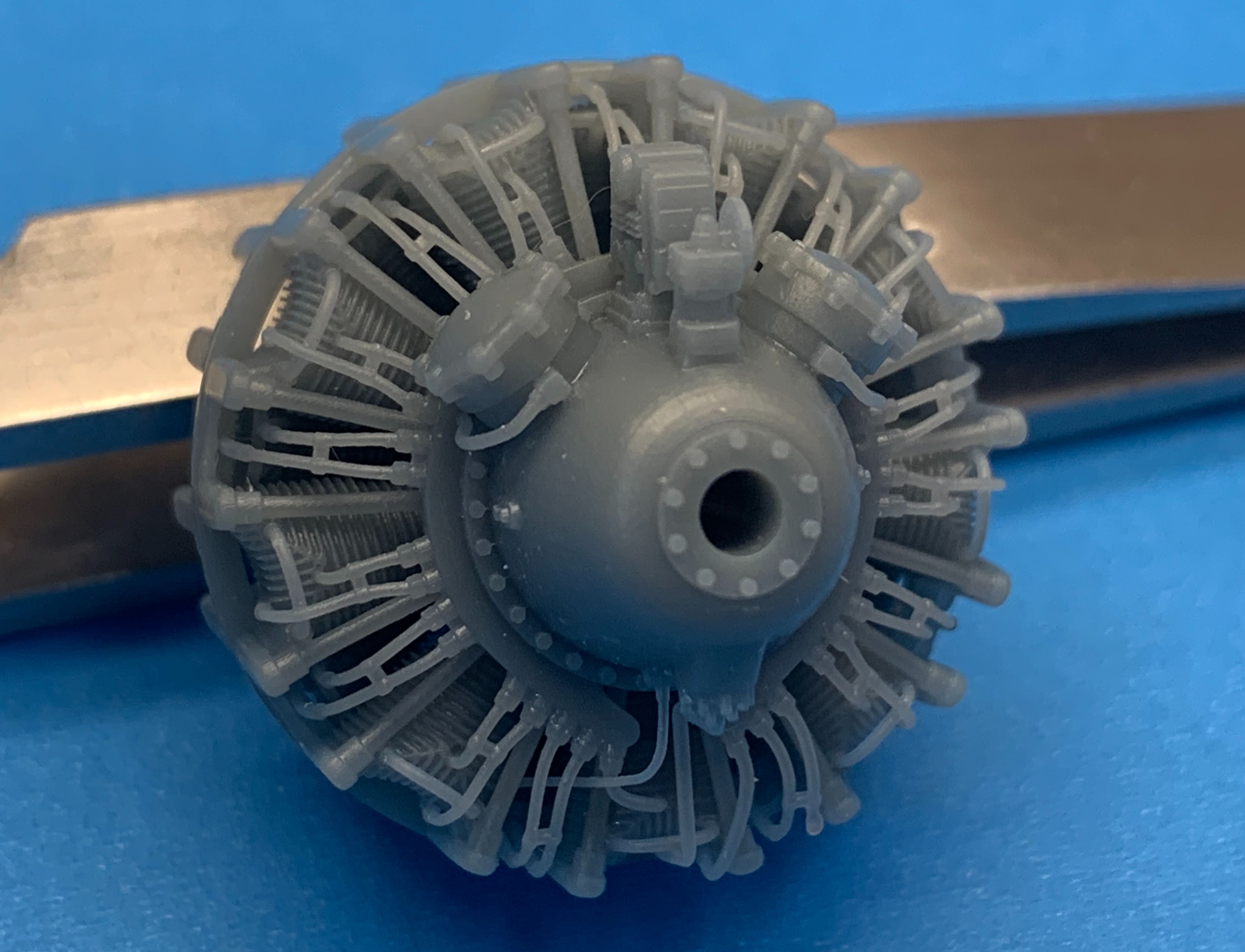

I am not, in any way, a tech guy and I doubt I will ever be designing my own 3D printed parts. Instead I have been picking these up more and more. Most recently was this 48th scale R-2800 engine. My friend, Tony Bell, made these and the pics he posted on Facebook impressed me enough to take two off his hands. Boy am I glad I did.

A few years ago, you only got detail like that from a resin piece. Now this is what can be achieved with (according to Tony) some knowhow, a ton of pictures and some 80 hours of design work (and probably a dozen test shots to fine tune). I can’t tell you what is next, or when it will happen but I am sure we will eventually get braided ignition lines, hex head bolts, and spark plug detail.

Despite the fact that I don’t have a Tamiya Corsair lined up for one of these beauties, I wanted to paint these engines right away and see how well I could preserve the detail. The only real prep work was to separate the engine from the support mounts. After that there is no need to scratch build wiring or plumbing. There was no adding individual push rods or those cylinder braces. Its all there in its wonderful time saving glory. All I did was carefully paint them and I was very happy with the results. I mean really, there is no match between the 3D part with the kit engine no matter how much I detailed it:

And it was finished in a fraction of the time.

If you are interested in how I did it, I made a video where I detail a simple process to paint these engines. I am sure it can be used for pretty much any 3D print. And, yeah, if you must stick with resin, I am sure the same painting process could apply.

Last Thing

Of course, there are a few more projects on the way that will include some resin with them. One I am working on right now and, well, the resin is first class stuff made by the master himself, Mike Belcher. But I tell you, I can’t see myself buying any more resin in the future.

How about you? Do you love your resin or are you ready to chuck it when you find some decent 3d printed replacements? Have you ever had a perfectly resin piece perfectly fit your project? Or, has it been always slog to use the stuff? Let me know in the comments.

Resin or 3D printed, I’m not especially “married” to either. I want what I want and if I can find that, how it’s made is secondary. I’m so accustomed to working (aka FITTING) resin that I almost don’t notice (up to and including making my own resin parts) the effort.

I checked into doing my own 3D printing and decided that the learning curve was far too steep and I’m not going to live long enough to make the effort of learning three different software suites AND how to run the printer worth the (rapidly diminishing) time I have left.

LikeLiked by 1 person

I’m of the firm belief that 3d design software needs to have its “Windows 95” moment. Like maybe we will see the mating of the design software with AI like a chatGPT.

LikeLike

T’would be nice…

LikeLike

While I’m sitting here sanding and filing resin engines for an F7F-3 produced by Quickboost, I’ve had another thought on the topic of 3D printing. The engines I’m working on are resin, however…from what I can tell, the *masters* were 3D printed. 3D printing is still relatively new tech and in coming years I suspect that the printing process itself could become quicker. Right now, however, it takes hours to do a print (and that time requirement goes up as the print becomes larger and/or more complicated). I can’t see someone going the 3D printing aftermarket route if they had to print EVERY gizmo they’d sold. Print the master, make molds, production time goes down. So I think that for now, we’ll see a hybrid of new and old tech.

LikeLiked by 1 person

Good points. The guy I got these engines from does multiple engine prints at a time and apparently there isn’t much time difference to the overall print time if he adds more engines.

LikeLiked by 1 person

Yes, I totally agree with you and rapierfighter. To be honest, I have never worked on resin in the past and unless something special is needed I don’t think I’ll be working with it. Also, I was an early Beacon Models investor on kickstarter and obtained their 3D prints of 1/144 pilots and Kübelwagen- amazing detail. I don’t even know how to start painting the figures!

LikeLike