I stopped by the LHS to check out a few things, pick up some paint and keep up to date with a few of the characters that frequent the shop. The owner and the staff have been very busy checking and prepping a mother lode of used kits that were recently acquired as a collection. I have my eye on a couple of these kits. If you are looking for anything aircraft related (some armor and ships too) keep checking back on his site, there will be a pile of them and they will be posted for sale in the next weeks.

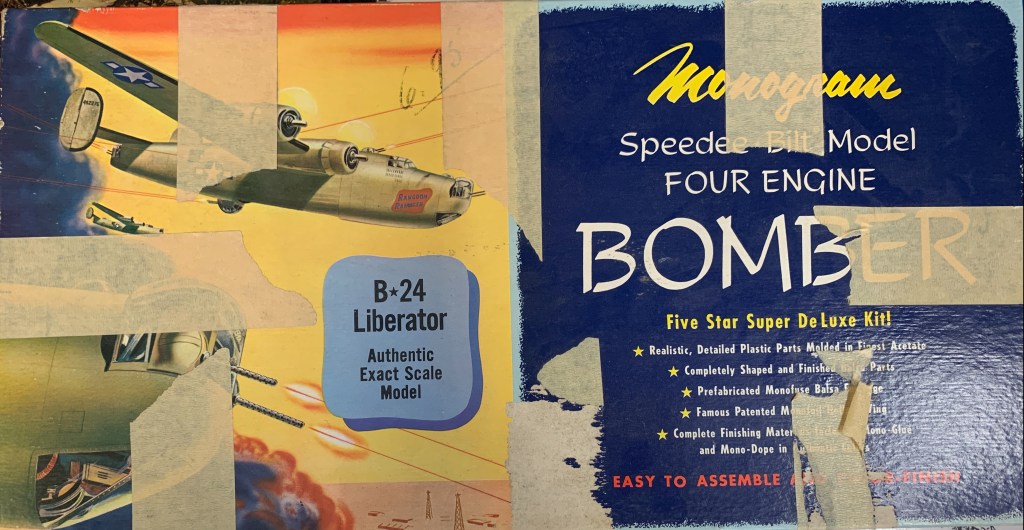

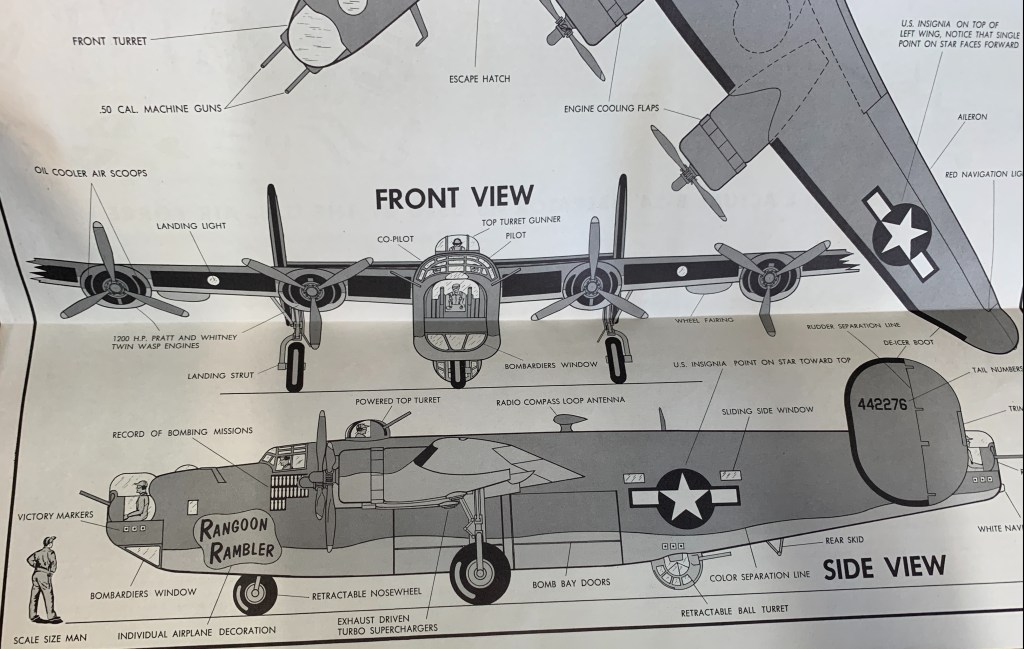

While the store has been busy with that, they have uploaded a video of a very old Monogram kit. After seeing the video, I wanted to see this 1958 kit in person because I think this thing was ahead of its time:

The box looked as if it contained a board game. Instead it contained one of the earliest ‘multimedia’ aircraft kits:

I’ll admit, this is no Eduard VLR Mustang Profipack, but it is far better than the block of wood and sandpaper builders used to get. It has pre-formed wood wings, injection molded engines, nacelles, props and cowls, and what I assume to be acetate for the clear parts. More importantly, there is paint in the form of dope as well as glue.

Where We’ve Been: Key Innovations

I started building kits in the late 70s or the early 80s. I can remember building car kits, planes and ships. They came in a box (with pictures of the actual model on the sides) and usually one bag containing all the sprues. That’s pretty bare bones. When I returned to the hobby in the later half of the 2000s the kits had better detail and may have been somewhat better engineered. But they were fundamentally the same. Since that time, it seems to me there have been some important innovations that have advanced the state of the hobby since my return to it in the mid-to-late 2000s.

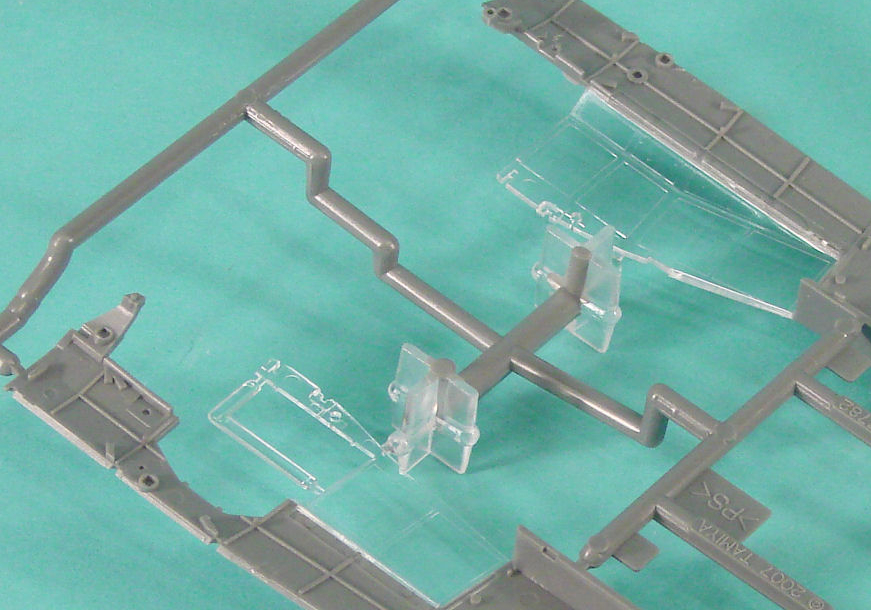

Multiple plastic colors molded on the same part.

This is a sprue shot from the 1/48 Tamiya Fi156 Storch. If you take a close look at the clear part you can see how it was molded into the regular styrene. The obvious benefit would be that builders would not need to be careful when attaching the canopy to the fuselage and that bond would be much stronger. I do not build much sci-fi or any gundam kits but I believe Bandai kits also combine multiple types and colors of plastic injected onto the same sprue but I am not sure they combine these onto a single part.

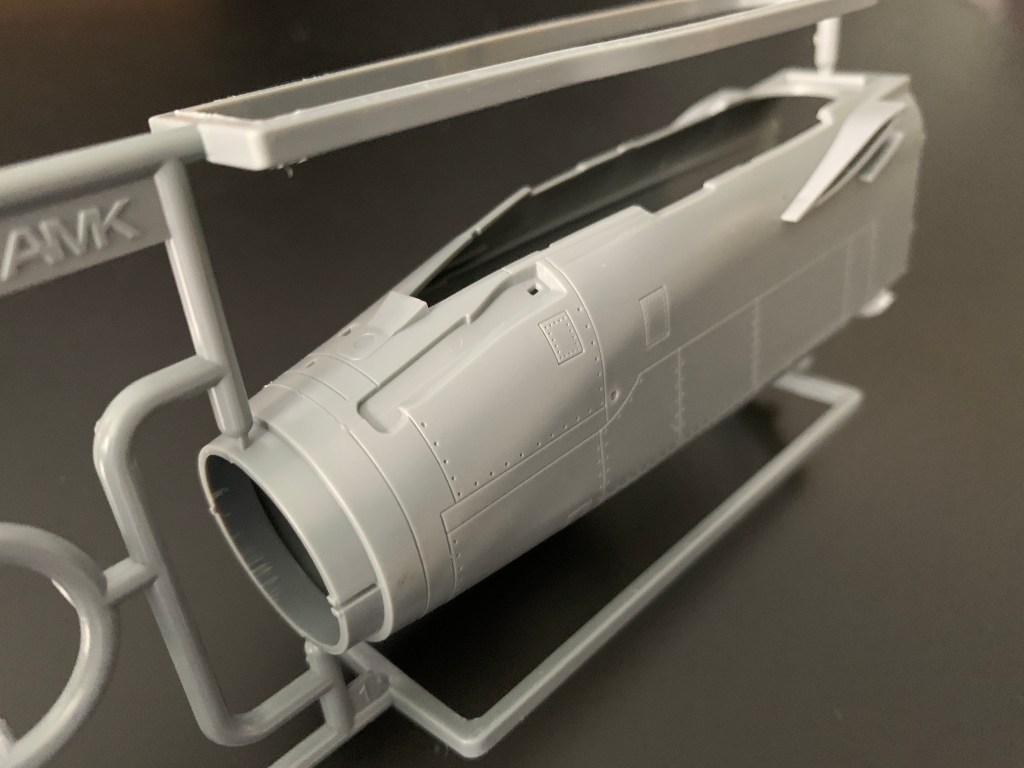

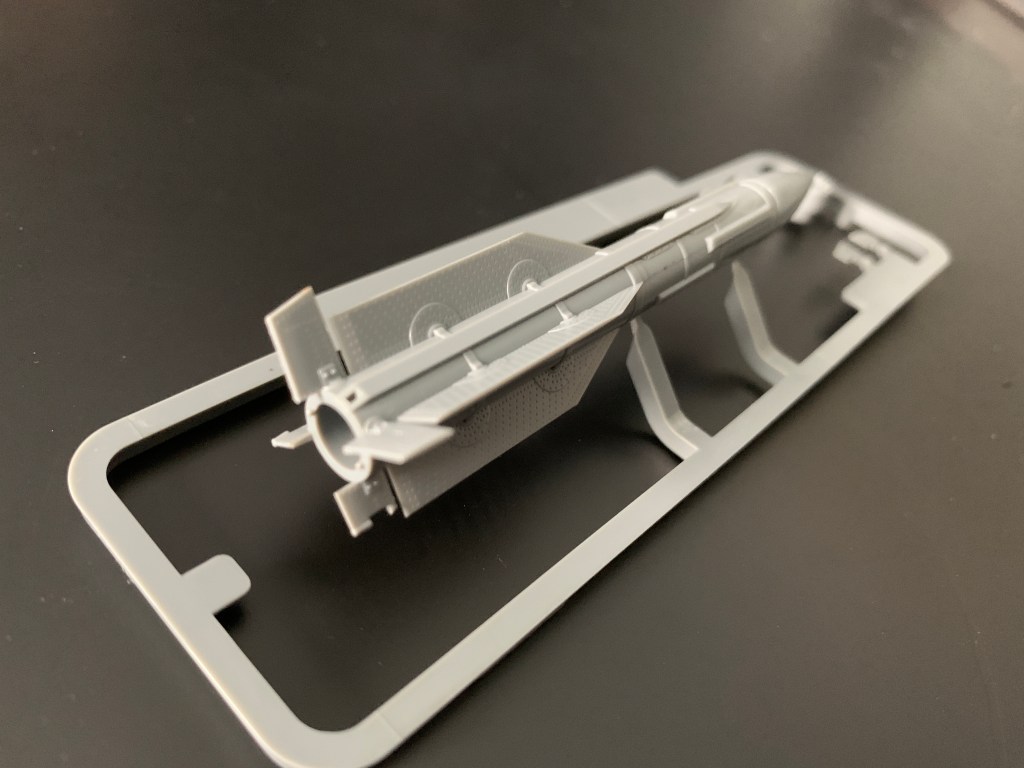

Slide Molding.

When it comes to closing up fuselages, 99% of the time you really can’t just put glue on everything and squeeze. You have to glue in sections making sure that both sides line up without a lip. Sometimes you get lucky and all you need to do is clean up a glue blob or two. Sometimes you don’t get so lucky and you have to carefully sand and polish the join. The problem is that no matter how well you manage the seam, the fuselage is circular and sanding can ‘flatten’ part of that perfect tube.

I have no idea who came up with slide molding or what kit was the first to feature it. The first time I ran into this technology was when I built my 1/200 Cyber Hobby XB-70. The entire “neck” section was one hollow tube and not only did it speed up the build, it eliminated that possible seam issue.

I picked up the AMK Mig-31 kit and the pictures above are the forward fuselage and one of the one piece missiles from that kit. I am very impressed with these pieces and that slide molding will make these bits just that much more easy to work with during instruction.

Modern kit engineering and nearly perfect fit.

I can’t say much about the armor guys but my recent builds of the Tamiya Lightning, the Tamiya Tony, the Finemolds Babs and the Arma Hobby Wildcat have been nothing but model building bliss. These modern kits fit together with precision. I believe that all makers have stepped up their game and are designing kits that no longer require putty and gap fillers to complete. I have been told that in some cases this precision has led to such tight tolerances where some kits cannot fit properly if there is paint on certain joins! I say that’s a great problem to have and what an incredible time saver in terms of actually completing the kits and displaying them.

Where I hope we go

I was recently asked where I thought the hobby of model making would be in 10 years. I am a practical person and I believe there will always be a segment of the population that likes to create things with their hands. I am sure model making, or something closely approximating it, will be here in 10, 20 and 50 years. Of course, I have no idea what it will look like. I just hope we can improve on a few things:

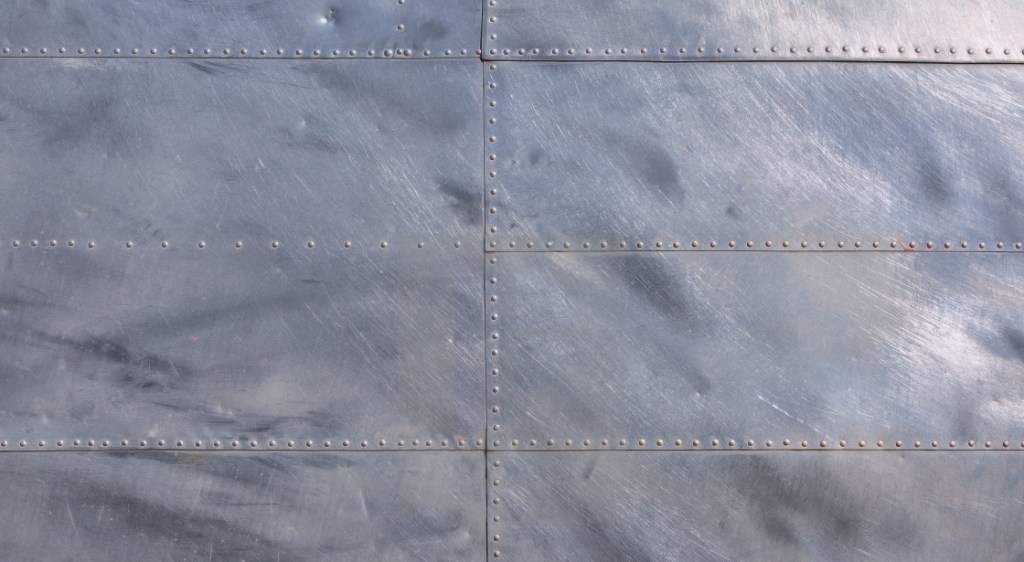

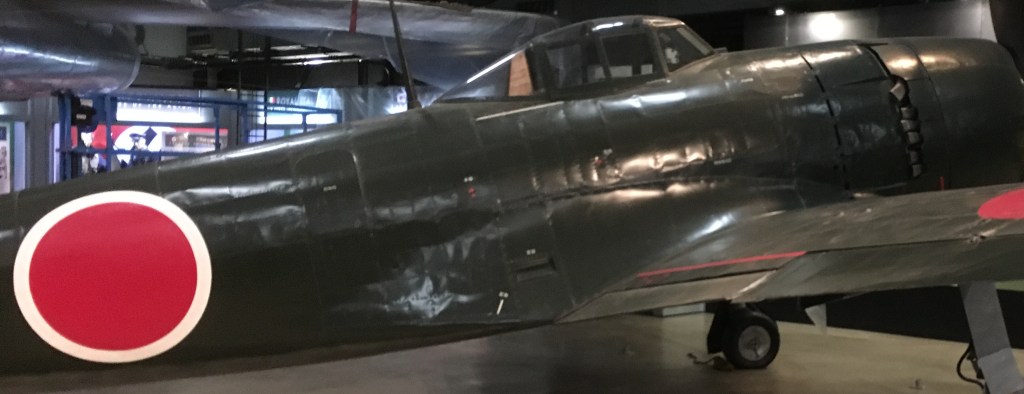

I want lapped joints and skin textures to be standard fare.

The world demands bigger and better. And the scale model world pushes for more detail and accuracy while pushing the technology to give us ever better construction engineering. For the longest time, I can remember the biggest worry about a kit purchase was whether the panel lines were raised or recessed. Then, as recessed lines became the norm, we worried about the fineness and uniformity of our recessed detail with words like “trench like” being used to describe the hack jobs.

I am a self described builder and I have never added red lines over top of model photos in order to present evidence of some manufacturing “lunacy” or kit “unbuildability”. That said, I appreciate fine detail as much as the next builder. We all know that airplanes do not have inch wide gaps between metal panels. We know this because we’ve seen airplanes from afar and up close. What we see is this:

This is a B-17 that has been incredibly well preserved and maintained. There may be a couple of panel lines (on the left side of the image) and there are definitely rivet lines all over. But there are far more lapped joins and skin ripples.

Granted, these are WW2 props and the appropriateness of this type of detail may be limited to these kinds of airplane. I had to comb through hundreds of pictures and I found that jet fighters to modern day planes do not have these skin effects but they do have skin textures:

Clear bits need to be thinner, clearer and easier to work with.

I’ve been making model airplanes for years and I have gotten to know clear plastic rather well and it has improved in clarity and thickness, especially in 1/32 scale. However, as we get to the smaller scales, it seems the clear parts are overly thick.

I know, there is always the vacuformed canopy alternative but you know something? They are no roaring heck either. Even if they are expertly removed from the sheet and perfectly fit to the fuselage (which takes considerable patience and skill) the canopy rails are very soft on detail while the canopy can be cloudy and distorted.

Since the multi-plastic-canopy-part in the Tamiya Storch kit mentioned above, Tamiya has simplified things a little by ‘extending’ the clear canopies to include a piece of fuselage that can be easily glued onto the kit. I think this is the way to go to improve this aspect of model airplanes and I am hoping we see even thinner and clearer canopies evolve with this easy method of attachment in all scales.

We really need an alternative to decals.

I want you to scroll up to the gallery for that decades old B-24 model kit. Everything in that box has been superseded by some technological development except one: the decals. In other words, we are still using 75+ year old tech and techniques to place markings on our models.

And it isn’t like this tech is at the pinnacle of human achievement. Actually, its the opposite. You see, no one remarks when one part of a kit glues to another part of a kit. No one calls their model buddies to tell them that primer and paint actually stuck to the model. Why is that? Because we should expect these basic things to happen.

Now, how many times are we surprised when the decals went on properly? We should not be texting our model buddies to tell them that a kit component did what it was supposed to do. But, when it comes to kit decals, this is exactly what we do.

Moreover, do we need two part potions to ensure the cockpit properly fits into the fuselage? And if the cockpit does not quite settle in, do we resort to stronger and stronger melanges of acids and bases over the course of weekday evenings? Not on your life. But, when it comes to kit decals, this is what we expect.

There has got to be another way to place precise markings on a kit. Yes, we can mask and paint larger designs and numbers but stencils and small art are difficult to reproduce this way. Right now modelers are creating precise custom parts by using lasers and pulling them out of resin goo baths. Surely some new tech will come along to replace decals, right?

Right?

Last Thing

I hope you enjoyed that look at that old Liberator model kit. I liked the ‘full meal deal’ aspect to it and the excellent component ‘presentation’ when the box was opened. It would be fun to see that sort of thing again. When it comes to summing up the last 20 years of kit tech, I may have missed some key innovations. Let me know if I did. Also, what do you think of my ‘wish list’? I guess that if there have not been any new methods of applying markings in over 70 years, then maybe I should buckle down and really work on my decal technique.

For me, I get along well with decals and applying them is a part of the build which I enjoy – in several realms, planes, tanks, trains, spacecraft, and flying model rockets.

LikeLiked by 2 people

A week ago I would have said decals seem pretty acceptable, but then I just had some come apart entirely on me! Very frustrating. But given the rarity of that sort of problem I still feel like the concept generally works pretty well.

My biggest frustration recently has to do with rigging. As a WWII modeler I don’t have to do a lot of it. But occasionally there is just no choice. I would love to see more pre-measured photo-etch or something. Maybe just accurate dimensions to make your own from wire or sprue. But as things stand now it makes me want to pull my hair out. Gee I wonder if I could make use of that…

Biplanes are also problematic for getting everything aligned. I don’t know if any new ideas are needed so much as good engineering practices; parts fit and positive locating.

An assurance of good and strong landing gear placement is always nice too. I’ve trashed a few models because of gear problems.

I do appreciate the improvements on clear part design, no shock Tamiya seems to lead the way on such things.

In general I’d like to see LESS photo-etch. I just groan when I see a bunch of gears or straps on a photo-etch fret. You know, those little things that will likely disappear just removing them, never minding bending, folding and mutilating into a physically impossible location. No doubt it has its uses (like the previously mentioned rigging!), but I feel like at least half the parts in any given set would be better done in plastic or resin.

LikeLiked by 2 people

That old Liberator kit is a work of art!

I’d like to see kit manufacturers pay attention to the standard appearance of an aircraft on the field, and provide that configuration right out of the box. Things like drooped flaps on Mustangs and extended leading edge slats on Bf-109s for example. There should always be the option to pose the canopy open with parts that fit in that position, and would it kill anyone to provide chocks?

LikeLiked by 3 people

This is uncanny timing on this subject, especially the clear parts/decal comments. I have been pondering this very question for months now.

Kits nowadays are spectacular for the most part… except for clear parts and decals. Decals, I can kind of handle, as long as they are good. What is frustrating, is when one gets a stellar kit (think new Tamiya releases) and everything is mind blowing except for the decals. I’ve built some of the newer Revell of Germany aircraft kits in 1/32 and their decals seem to be way better. I think they are Cartograph. Why doesn’t Tamiya and some of the others just let the decal experts make decals for them? But, better still, new technology would be a very welcome change.

Clear parts… another area that is lacking. I just built the Arma Hobby 1/72 Hurricane MkIIc Trop and it is a terrific kit. Except for the canopy/windsceen. Ultra thick! If the cockpit is closed up, it doesn’t make as much of a difference, but then all of that nifty detail inside is hidden.

Hopefully, manufacturers will figure this stuff out, and I’m sure it’s only a matter of time.

Great post!

LikeLiked by 1 person

Interesting comments, not only in your post but in some of the responses. Yeah, I’m down with doing clear parts differently than has been the norm. I really like how Tamiya did the canopy of their stellar new P-38 kits!

Decals are more variable than I like. Some kits have outstanding decals (Trumpeter’s A-37B kit for example) and some are anything but outstanding (Bronco’s Early Production M24 and, surprising me no end, Tamiya’s new-tool P-38 decals, the stars in particular, were not up to the standard of the rest of that kit). Even Cartograph can be inconsistent (heresy…I know) (their SR-71 decals sheet left more to be desired than I’m accustomed to from them). Until recently, I tried to use dry transfers whenever possible, but the last company that manufactured materials required to produce dry transfers has shut down permanently and dry transfers aren’t being produced anymore (insert industrial-grade whining here). For the relatively easy markings, stripes, stars, and things of that nature, I’ll often rely on paint.

With the prevalence of CAD/CAM, 3D printing, and computer graphics (replacing silk screens for decal inking), the potential for fit and accuracy has taken massive leaps forward. But never underestimate the human potential for voiding the bladder in the breakfast cereal. Bronco’s Early Production M24 could serve as a disappointing warning of how computer technology can produce disappointing results. For a new tool kit where CAD/CAM is used, fit was laughable (particularly the rear deck over the engine bay), parts count was ludicrously high without purpose, and the incorporation of “workable features” was simply stupid (this ain’t the Sixties, y’know, where they weren’t models as much as they were plastic toys we assembled). I’m all for posable features, however. Human sloppiness and/or stupidity cannot be offset by CAD/CAM technology.

(As an aside, for rigging I use EZ Line. Great stuff, that! Fine, consistent diameter, unlike stretched sprue, and slightly elastic which allows for sag-free installations. I used EZ Line on both the P-51 and P-38F I did. Worked great.)

LikeLiked by 2 people

I’m in two minds about this post. On the one hand there is no denying that modern day kits are a considerable improvement over that B-24 kit but on the other hand how much more do we want kits to improve before there is no challenge at all in putting them together? (Do we want our kits to come pre-made?) More importantly, the improvements that may seem desirable in the larger scales would be redundant or unnecessary in smaller scales, and I’m a 1/72 and 1/144 kinda guy.

I think that the improvements you want are those which seem important to a modeller who works in a larger scale and puts a premium on detail. Lapped joints and skin texture might seem important in 1/32 or 1/48 but are much less important in 1/72 where a couple of coats of paint will obscure that detail and completely unnecessary in 1/144. Clear parts that are scale thickness in larger scales become too fragile to use in smaller scales. And so on with other differences in requirements and the techniques used in different scales.

Don’t get me started on drooping flaps and slats. Maybe okay in larger scales but the Zvezda 1/144 Airbus A.320 offers drooped slats and flaps and it is well nigh impossible to make the model as you would normally see it at the terminal gate with the slats and flaps up without too much filling and sanding.

On the business of decals, maybe it’s old technology but so is injection moulding and I don’t see you complaining about having to liberate parts from the sprues. There are techniques for doing that and there are techniques for laying down decals successfully too – including the problem of exploding decals. And if you don’t like what’s in the box the offerings in aftermaket decals is enormous.

In summary, your suggestions seem self indulgent to me, but then I don’t make the kinds of models that your requests are relevant to. I’m more than happy with the standards of 1/72 kits as they have been for the past twenty years and if I am unhappy with parts such as ejector seats, cockpit interiors or armament I just order aftermarket parts too. When it comes to decals, some kit makers do a good job and the aftermarket suppliers do even better. My only trouble is rigging, but I doubt there is an easy solution to that one.

LikeLiked by 1 person

I have a bunch of vintage Mknogram kits… can I retire now?

On Mon, Jul 26, 2021 at 11:42 PM Model Airplane Maker wrote:

> ModelAirplaneMaker posted: ” I stopped by the LHS to check out a few > things, pick up some paint and keep up to date with a few of the characters > that frequent the shop. The owner and the staff have been very busy > checking and prepping a mother lode of used kits that were recently ” >

LikeLiked by 1 person

You’d need an awful lot of them.

LikeLike